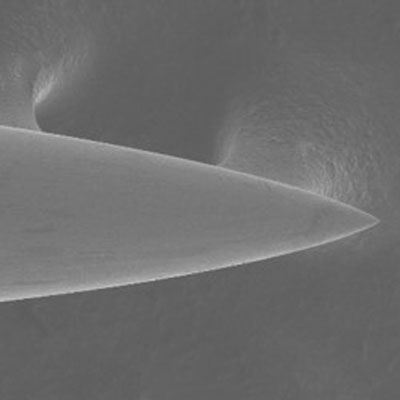

World class polishing technology leading to painless treatments

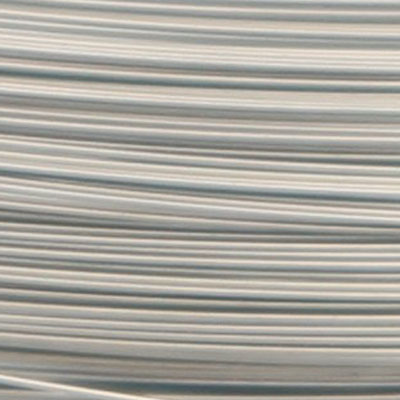

Use of high-quality raw materials manufactured 100% in Korea

Customized production meeting customer needs

Ensuring cleaner manufacturing environment for our needles

Dana Medical is a reliable company based on 23 years of accumulated technology and know-how.